Product Features

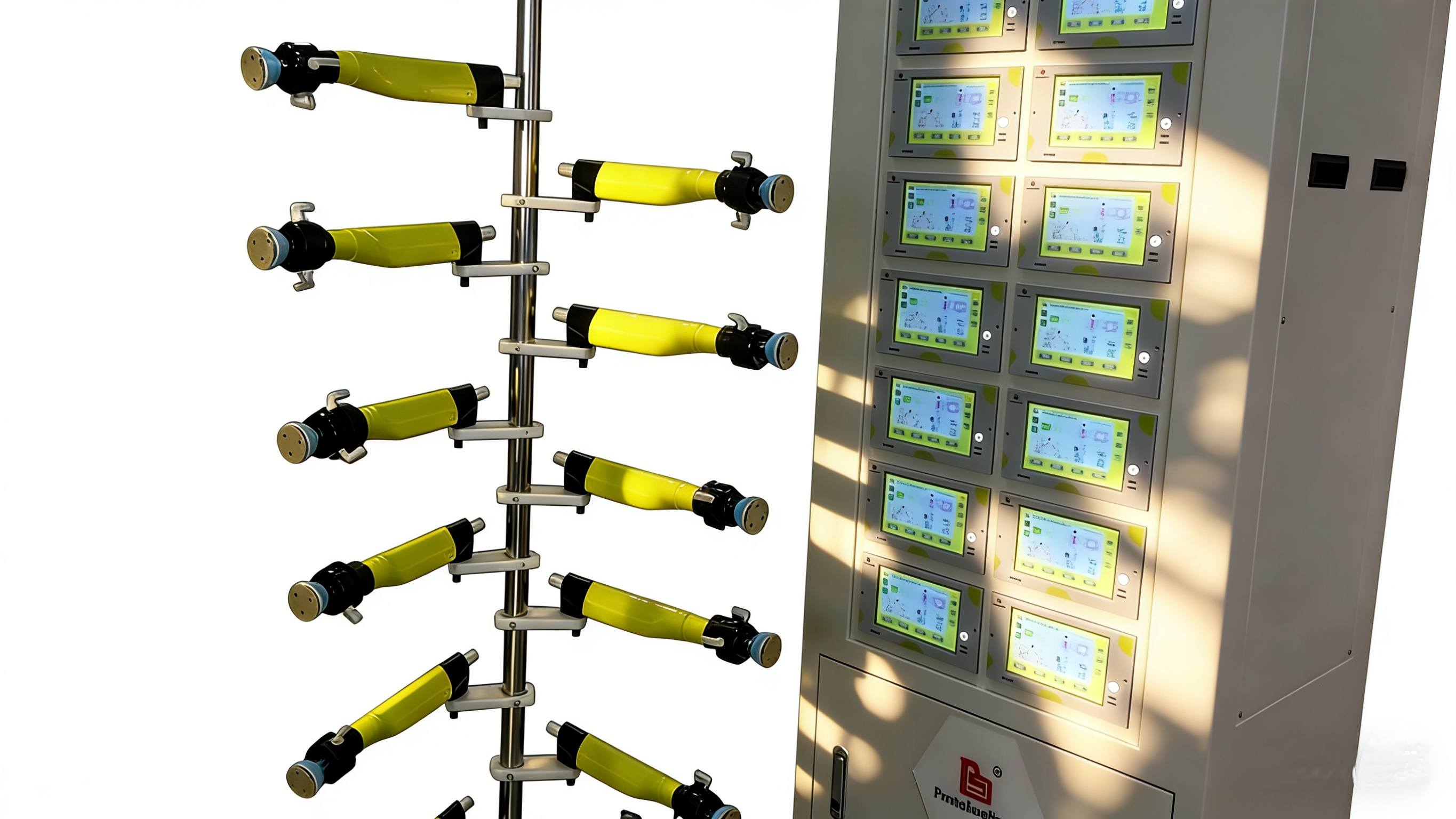

1. Intelligent Interconnection and Strong Automation Adaptability

Supports multiple automation control protocols, enabling quick integration with industrial robots, reciprocating sprayers, and conveyor lines for precise spray path planning, workpiece positioning and tracking, and continuous operation. Equipped with multiple sets of spray parameter storage functions, allowing pre-setting of parameters such as rotation speed, powder output, and electrostatic voltage for different workpieces, enabling one-click recall when switching workpieces, adapting to small-batch, multi-variety production needs. The equipment includes a real-time status monitoring module that provides early warnings for abnormal rotation speed, pressure fluctuations, and electrostatic faults, reducing downtime losses and improving production line stability.

2. Efficient Atomization and Excellent Spraying Performance

Equipped with a powder spray cup design, the powder is atomized into uniform, fine particles under centrifugal force, improving atomization particle size consistency by more than 30%; the optimized powder flow channel and shaping air adjustment system precisely control the powder quantity and film thickness.

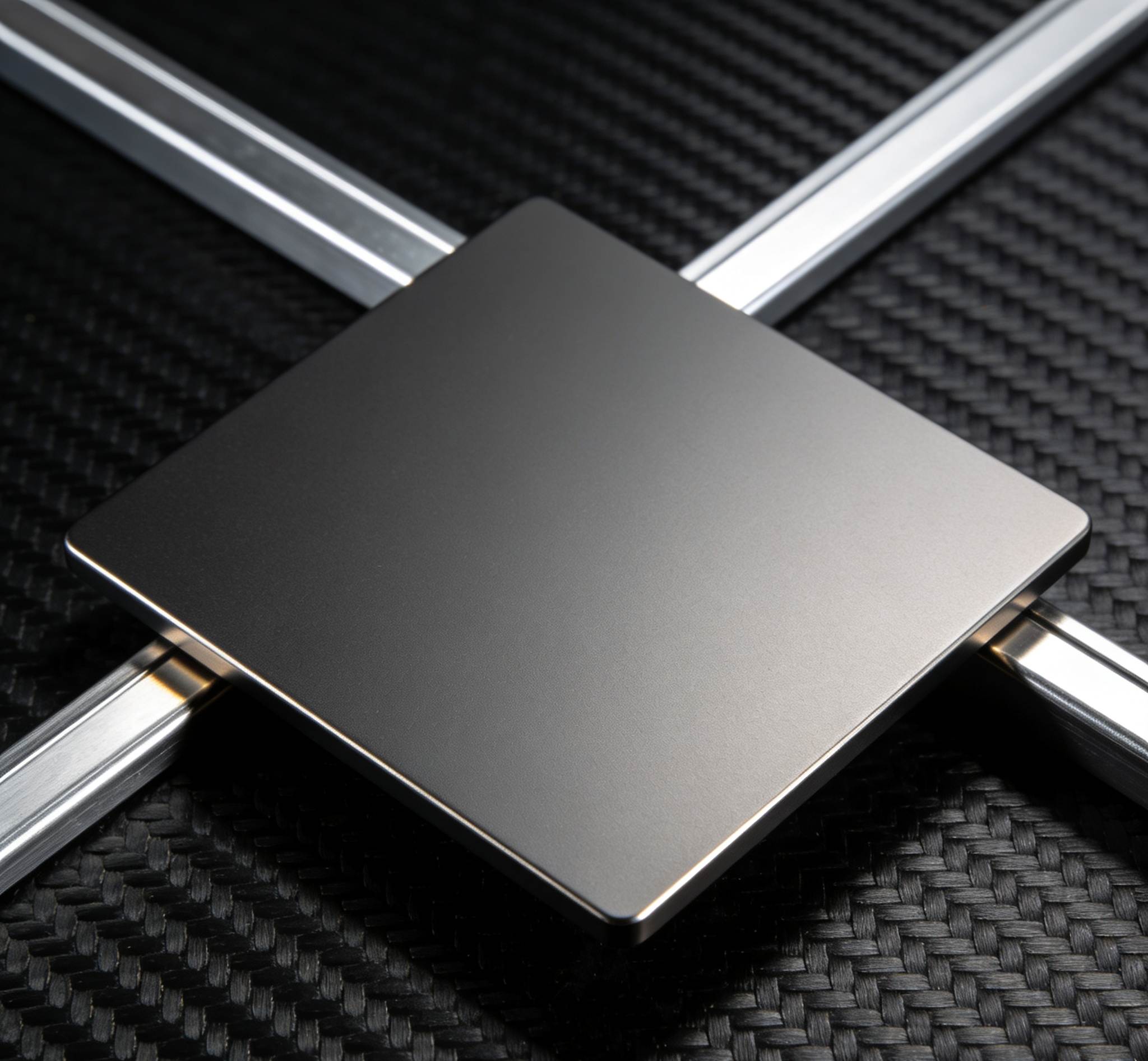

3. Precise Electrostatic Control and Excellent Coating Quality

Adopts a constant voltage and constant current dual-mode electrostatic control system, with an output voltage of 10-100kV continuously adjustable. The electrostatic output is stable, with a decay rate of ≤5%, ensuring uniform charging of powder particles and stronger adhesion; coupled with a multi-electrode distributed layout, it enhances electrostatic coverage of irregularly shaped workpieces and blind spots, effectively avoiding missed and incomplete spraying. The coating thickness error can be controlled within ±5μm, resulting in a flat and smooth surface without sagging or pinhole defects.

4. One-Click Cleaning, Improved Efficiency

One-click cleaning of the spray gun simplifies the cleaning process and improves worker efficiency.

Application Scenarios

Ultra-wide atomization range of 80-330mm, suitable for various small hardware components such as handles and hinges. Provides uniform coating without thickness variations and no bare spots at edges and corners.Precise electrostatic control from 0-100kV ensures strong powder adhesion, reducing rebound and powder waste, significantly lowering the cost of batch spraying small workpieces. The lightweight body is ideal for robotic operation, enabling high-frequency reciprocating spraying without jamming, doubling the production efficiency of small hardware components.

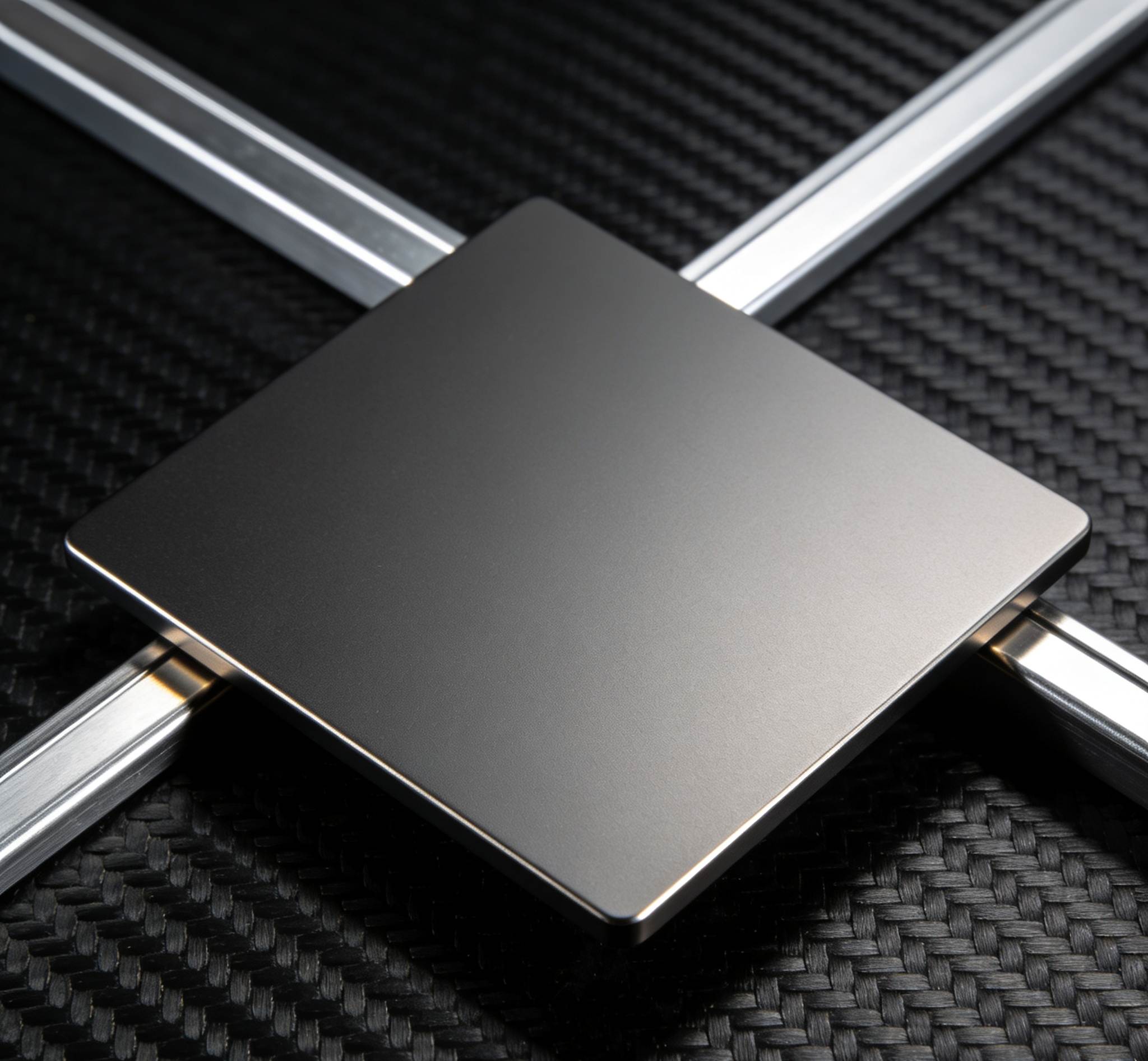

Electronic touch controls allow for precise parameter adjustment. For large components such as refrigerator sheet metal and air conditioner outer panels, the coating thickness is consistent, and the texture is comparable to the original factory finish. 485 communication links with PLC/robots, ensuring complete coverage even on complex curved surfaces (such as appliance brackets), perfectly adapting to the diverse manufacturing processes of appliance metal parts. Stable high-voltage electrostatic application ensures the powder adheres firmly to the appliance metal substrate surface, providing scratch and wear resistance, and meeting appliance product quality inspection standards.

With an ultra-large powder output of 30-1000g/min, it's ideal for large-area spraying of metal decorative panels, electrical substrates, and other surfaces, ensuring efficient and uniform film formation without streaks. The ultra-high-speed bearing-driven rotary cup provides fine and even atomization, resulting in high flatness of the flat panel coating, with one-button switching between mirror and matte finishes. Multiple installation options allow for flexible adaptation to production lines, ensuring maximum consistency for batch spraying of flat workpieces, whether in fixed spraying or robotic applications.