Product Features

1. High-Efficiency Spraying, Production Capacity Leap

This product utilizes a self-developed dustproof turbine motor, combined with an optimized powder flow structure and the strong centrifugal force generated by high-speed rotation, to fully atomize the powder. Coupled with application-specific nozzles, it significantly improves the spraying quality of workpieces. Most workpieces can be sprayed in a single pass, avoiding rework and further increasing production capacity.

2. Precise Coating, Excellent Quality

Equipped with constant voltage and constant current electrostatic technology, the output voltage can reach up to 90kV, ensuring uniform and stable high-voltage electrostatic during the spraying process, minimizing electrostatic decay, and ensuring uniform charging and strong adhesion of powder particles. Combined with a multi-electrode distributed layout and a conical baffle rebound design, it increases the contact opportunities between the powder and the electrodes, improving overall charging efficiency, effectively avoiding the waste of uncharged powder. The coating uniformity is excellent, and the film thickness is highly controllable, allowing for precise control of coating thickness, reducing defects such as sagging and edge burning, and resulting in a flat and smooth coating effect.

3. Wide Adaptability, Flexible and Versatile

Adopting a modular design, it supports various diameter cup head options to meet the spraying needs of workpieces of different sizes and shapes. Installation methods are flexible and diverse, allowing for selection of lift installation, fixed installation, or robot installation depending on the application environment. It is also compatible with handheld and automatic powder guns, and is compatible with various mainstream powder gun brands domestically and internationally, allowing for upgrades without replacing the entire spraying equipment, significantly reducing equipment update costs.

4. Green and Energy-Saving, Cost Optimization

Integrating dense-phase conveying technology, the powder conveying is stable and precise, effectively improving powder control accuracy, resulting in a high first-pass powder application rate and significantly reducing powder waste, lowering raw material costs. Combined with the application of environmentally friendly powder coatings, it avoids the harmful gas emissions of traditional solvent-based coatings, meeting stringent environmental regulations. At the same time, the low-energy consumption component design reduces equipment operating energy consumption, comprehensively achieving green energy saving and cost optimization in the coating process.

Application Scenarios

Under soft lighting, the metal table frame components, after being evenly coated by a rotary cup spray nozzle, are covered with a delicate and flawless matte finish. Every edge and corner of each table leg is completely covered by the coating, without any drips or missed spots. The natural, woodsy background further highlights the high-quality texture of the coating, perfectly matching the quality requirements of luxury furniture.

This vintage-style wrought iron fence component, under the precise atomized spray coating of a rotary cup nozzle, features a coating that adheres firmly to every carved and bent section. The color is rich and uniform, with no powder accumulation or bare spots even in the crevices and corners of the wrought iron. The overall result is a durable, rust-resistant, high-quality coating, perfectly suited for outdoor iron furniture.

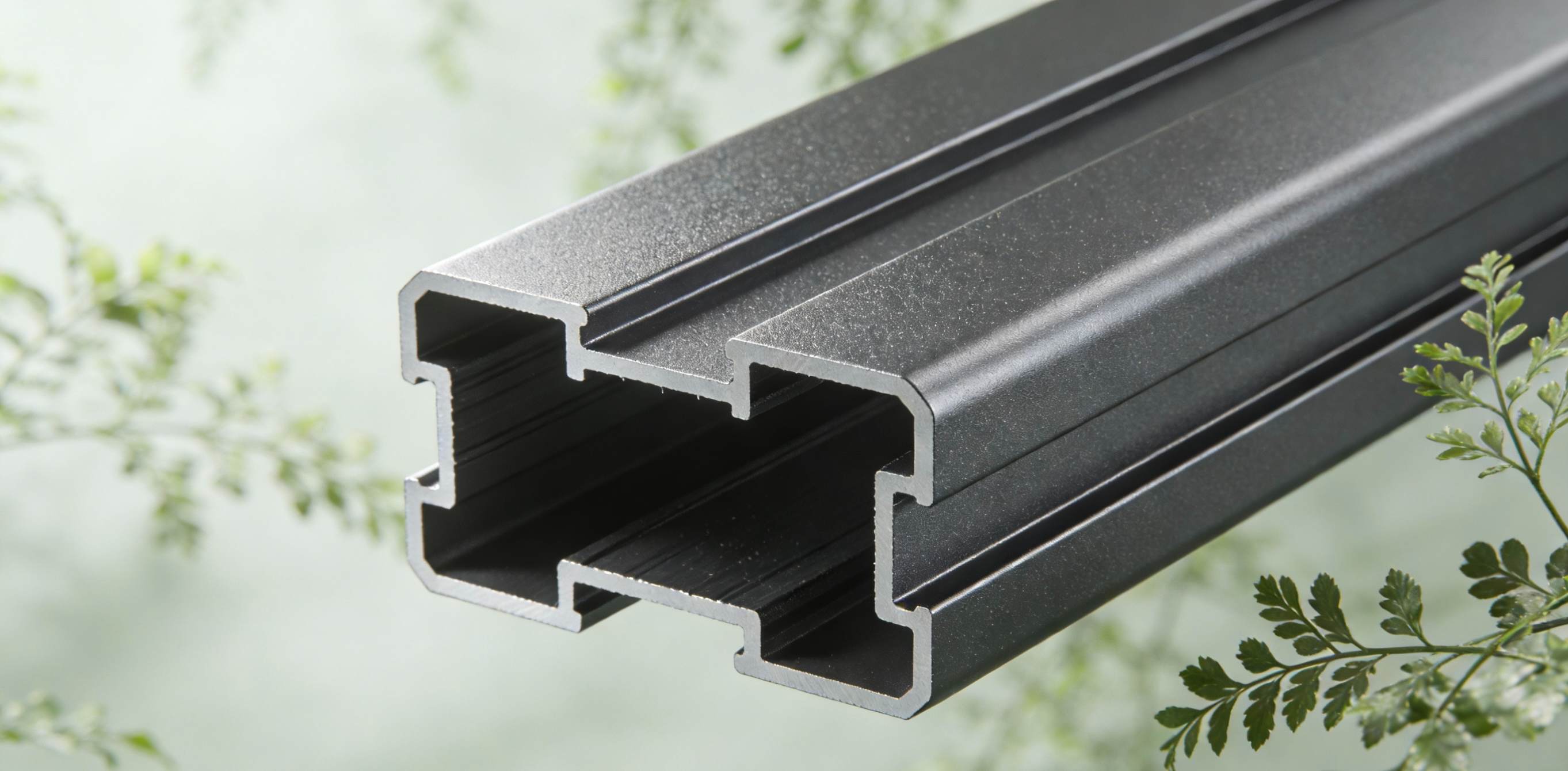

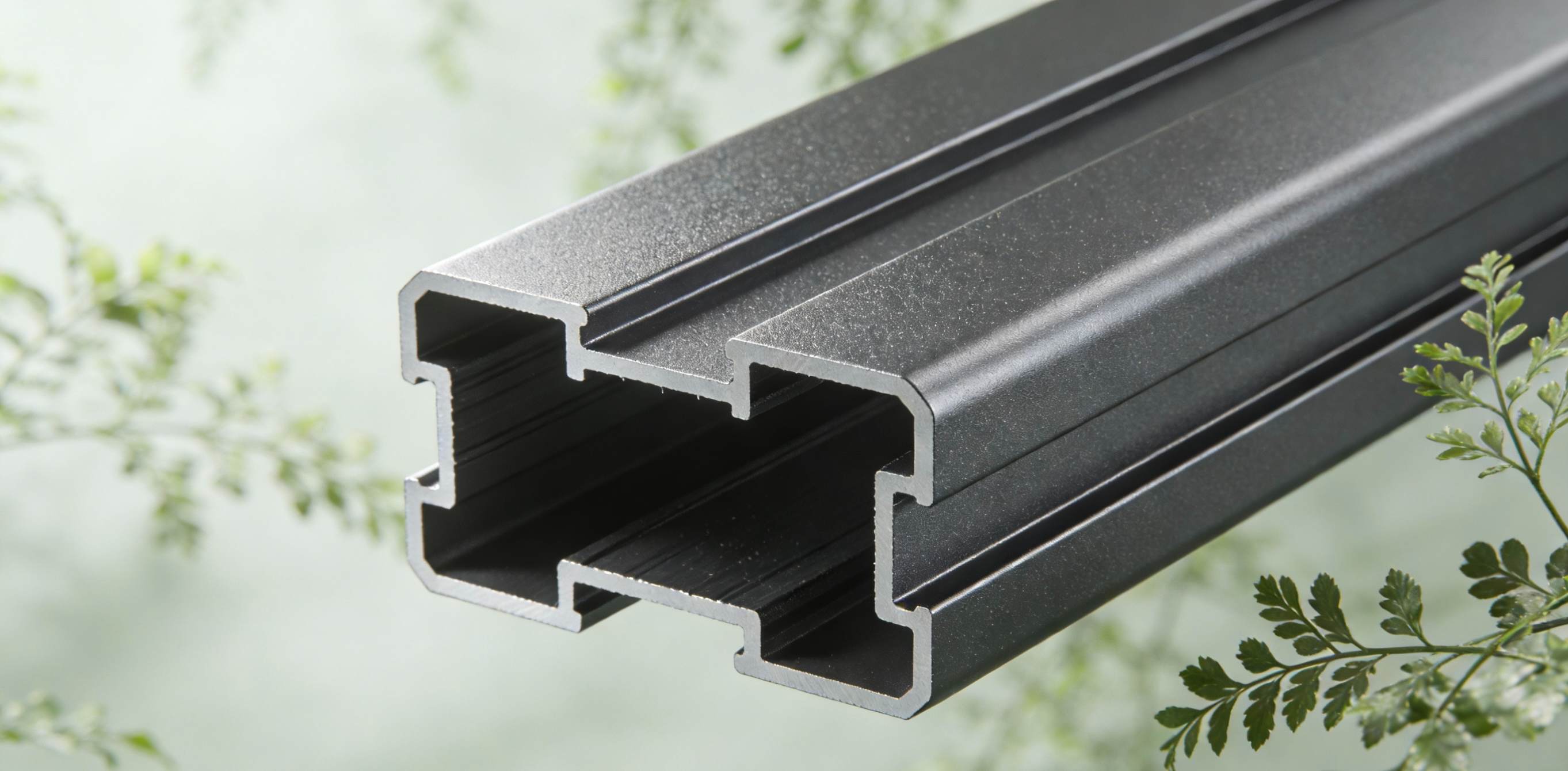

The extra-long industrial aluminum profile frame workpiece was seamlessly coated using a rotary cup spray nozzle with a high powder output and high-speed spraying mode. This resulted in a uniform and consistent coating thickness across the entire profile, with the grooves and joints of the profile being densely filled with the coating material. There was no noticeable color difference under strong light, perfectly meeting the high standards and strict requirements for aluminum profile coating in industrial production lines.