Empowering Aluminum Profiles and Kitchen & Bathroom Products with Eco-Friendly, High-Quality Powder Coating

As environmental coating requirements continue to rise, powder coating is gradually replacing traditional liquid paint, and the application of rotary bell spray guns in the building materials sector is expanding rapidly.

Application Areas:

- Aluminum Profiles: Architectural curtain wall aluminum profiles, aluminum frames for doors and windows, and partition aluminum profiles. Rotary bell spray guns ensure smooth, sag-free coatings with minimal color variation, meeting stringent requirements for architectural appearance and long-term durability.

- Kitchen & Bathroom Products: Stainless steel sinks, metal bathroom cabinets, water heater housings, and metal panels for range hoods. The coatings provide excellent water resistance and oil-repellent properties.

With growing awareness of environmental protection and continuous upgrades in industry coating standards, powder coating technology—known for its eco-friendly nature and superior performance—is rapidly replacing traditional liquid paint systems and becoming the mainstream choice in the building materials and home furnishing industry. As the core equipment of advanced powder coating technology, powder rotary bell spray guns are seeing increasingly broad application scenarios, from architectural aluminum profiles on building façades to kitchen and bathroom products used in everyday life. They inject strong momentum into the industry’s green transformation and quality enhancement.

Aluminum Profiles

Aluminum profiles are essential materials in the building materials industry and are widely used in architectural curtain walls, door and window frames, and interior partitions. Surface coating quality not only directly affects the overall aesthetic of a building but also determines product durability and long-term safety.

Curtain wall aluminum profiles are exposed to outdoor environments for extended periods and must withstand wind, sunlight, rain, snow, and temperature fluctuations. Aluminum frames for doors, windows, and partitions must also resist daily wear and scratching while maintaining uniform color and flawless appearance.

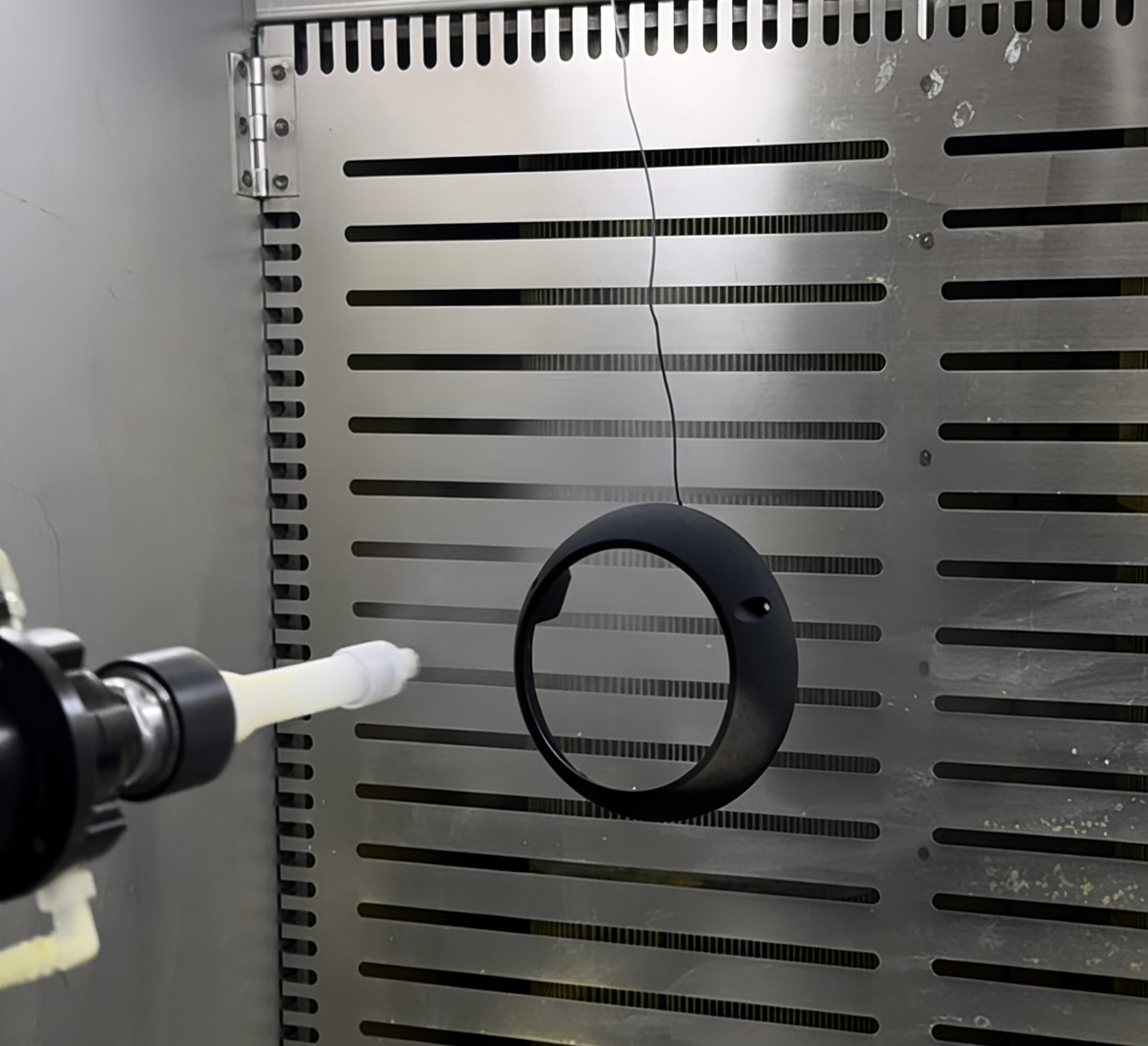

Thanks to precise spray control, powder rotary bell spray guns effectively address the core challenges of aluminum profile coating. The resulting coating thickness is uniform and consistent, eliminating common defects found in traditional spraying processes, such as sagging and particle formation. Minimal color variation ensures a consistent appearance across large-scale production, meeting the strict aesthetic requirements of architectural projects.

In addition, the coating bonds tightly with the aluminum substrate and offers excellent corrosion resistance, weather resistance, and wear resistance. This effectively protects the profiles from environmental damage, extends service life, and ensures long-term safety and visual appeal. Whether for modern high-rise curtain walls or residential door and window partitions, powder rotary bell spray guns provide aluminum profiles with both visual elegance and robust protection.

Kitchen & Bathroom Home Products

Kitchen and bathroom products are closely tied to daily life, and their surface coatings must deliver not only aesthetic appeal but also practical functionality.

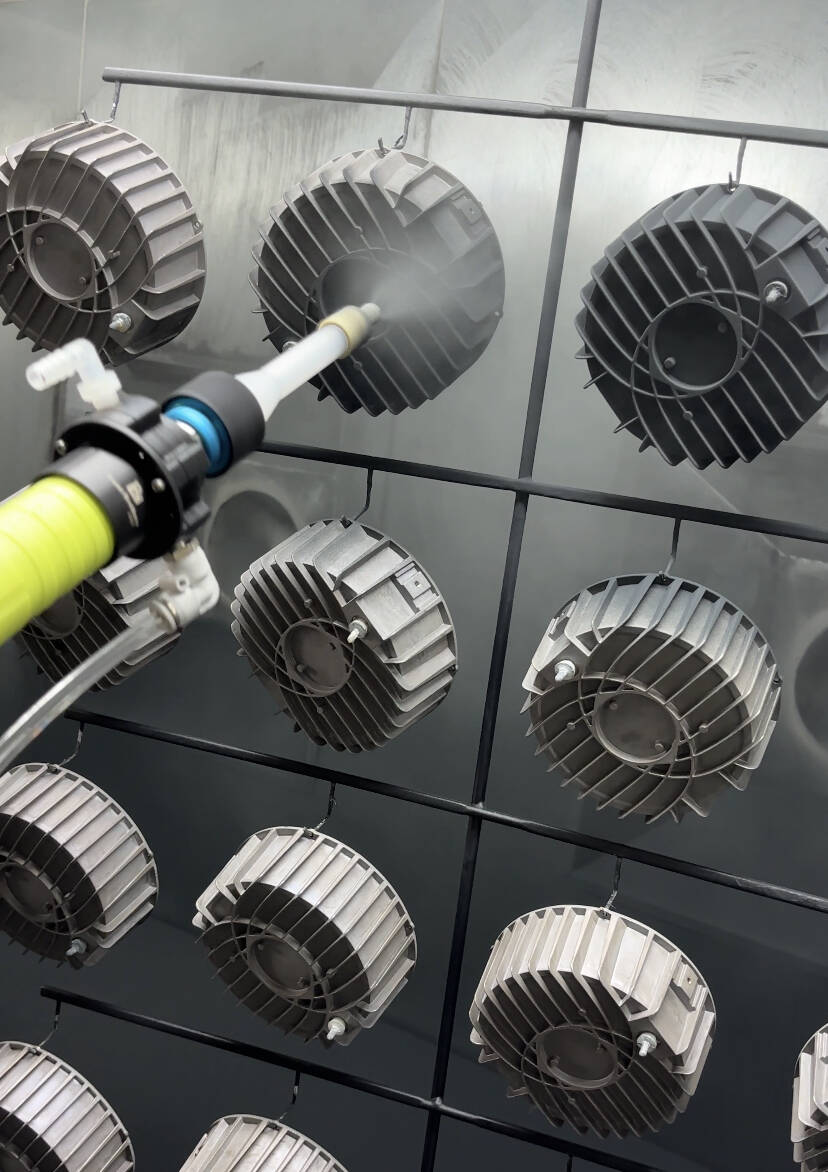

Stainless steel sinks are exposed daily to water, detergents, and food residues, requiring exceptional water resistance, corrosion resistance, and scratch resistance. Metal bathroom cabinets are used in consistently humid environments, making moisture and rust resistance essential. Water heater housings and metal panels of range hoods must withstand oil contamination and high temperatures while remaining easy to clean.

Powder rotary bell spray guns achieve a perfect balance between functionality and aesthetics for kitchen and bathroom applications. The coatings provide outstanding water- and oil-repellent properties, allowing liquids and grease to slide off easily without adhesion. This makes daily cleaning of sinks and range hood panels simple and efficient.

At the same time, the coatings feature high hardness and strong wear resistance, effectively protecting products from scratches and impacts during daily use and maintaining a clean, refined appearance. Moreover, powder coatings contain no organic solvents, making them environmentally friendly and non-polluting—fully compliant with health and safety requirements for home environments. Consumers can enjoy high-quality kitchen and bathroom products while benefiting from a green, sustainable living space.

From pristine kitchen sinks to elegantly designed bathroom cabinets, powder rotary bell spray guns enhance kitchen and bathroom products with superior coating performance, improving overall comfort and quality of life.

Industry Value & Future Outlook

The widespread adoption of powder rotary bell spray guns in the building materials and home furnishing industry reflects both the industry’s response to environmental regulations and the market’s increasing demand for higher product quality.

Their core advantages are clear. On one hand, high powder utilization enabled by advanced electrostatic technology significantly reduces material waste, lowering production costs and minimizing environmental emissions—fully aligned with the development of eco-friendly coating solutions. On the other hand, coating performance far exceeds that of traditional liquid paint systems, meeting the stringent requirements of building materials and home products across diverse usage scenarios. In addition, the technology is well-suited for large-scale, standardized production, helping manufacturers improve efficiency and maintain consistent product quality.

As consumer expectations for home quality and environmental sustainability continue to rise, and as the construction industry transitions toward green, low-carbon, and premium development, the application of powder rotary bell spray guns in the building materials and home furnishing sector will continue to expand.

Looking ahead, ongoing advancements in coating technology will enable powder rotary bell spray guns to deliver more customized finishes and enhanced functional performance—bringing greater innovation potential to the building materials and home furnishing industry and driving it toward a greener, higher-quality, and more efficient future.