Covering Wheels / Interiors / Battery Components with High Efficiency, Eco-Friendly Performance, and Full Automation Compatibility

The automotive industry is one of the primary application areas for high-end powder coating technologies, where rotary bell spray guns are widely used.

Applicable Products:

Automotive wheels (powder coating of aluminum alloy wheels is a core application), vehicle body metal structural components (door frames, chassis protection parts), interior metal components (seat rails, metal parts of air-conditioning vents), and battery housings and brackets for new energy vehicles (NEVs).

In the automotive and automotive components industry, where high quality and reliability are paramount, advanced powder coating technology has become a critical factor in enhancing both product performance and aesthetics. With its outstanding coating capabilities, the powder rotary bell spray gun has emerged as one of the most widely applied core pieces of equipment in this field.

From wheels that support vehicle mobility to body structural components that ensure safety, from interior metal parts that elevate driving comfort to battery components that empower new energy vehicles, powder rotary bell spray guns deliver precise, efficient, and high-quality coating performance—injecting strong momentum into the high-quality development of the automotive industry.

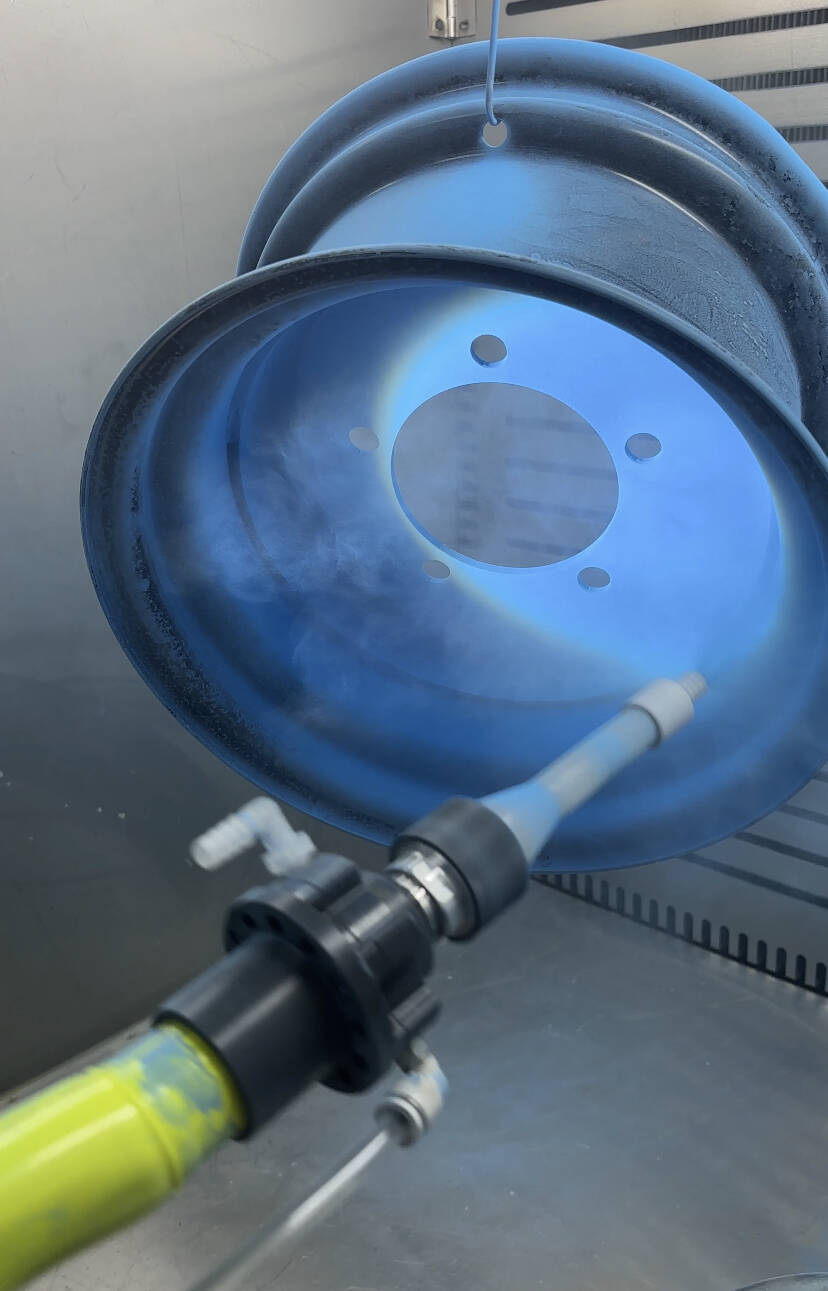

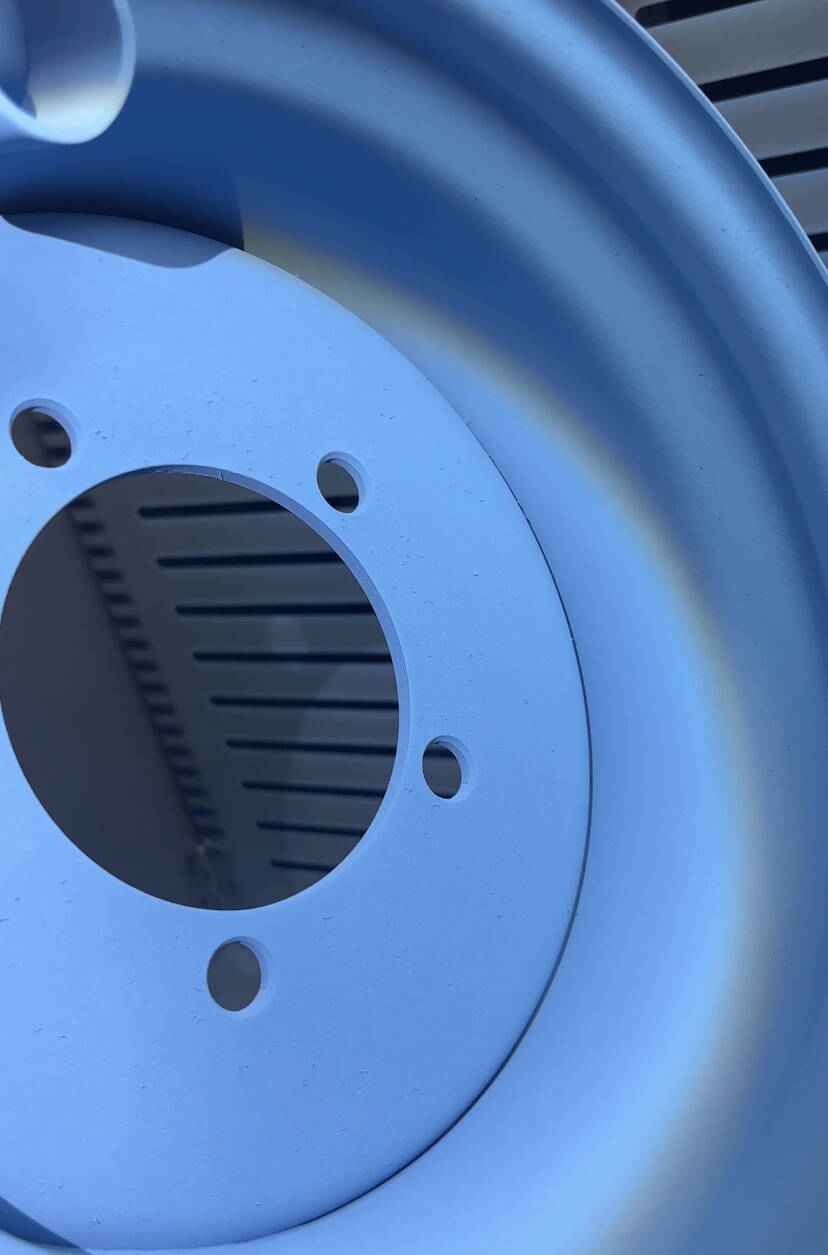

Automotive Wheels

Automotive wheels, often regarded as the “feet” of a vehicle, not only bear the vehicle’s weight but also play a key role in defining its visual appeal. Among them, powder coating of aluminum alloy wheels has become a core application scenario for rotary bell spray guns.

Although aluminum alloy is lightweight and corrosion-resistant, it has relatively low surface hardness and is prone to scratches. Long-term exposure to complex road conditions and varying climates demands exceptional weather resistance and wear resistance. Leveraging high electrostatic transfer efficiency, powder rotary bell spray guns ensure that powder coatings are evenly deposited on the wheel surface, forming a dense and smooth coating layer. This significantly enhances hardness and scratch resistance, protects against damage from stone impacts and road friction, and improves corrosion resistance to withstand rain, mud, and debris.

At the same time, the uniform coating provides rich color saturation and a refined texture, meeting the automotive industry’s stringent aesthetic standards and adding distinctive visual appeal to vehicles.

Body Metal Structural Components

Body metal structural components are the core carriers of vehicle safety performance. Components such as door frames and chassis protection parts are directly related to vehicle rigidity and safety, requiring surface protection that meets the highest industry standards.

Door frames must endure long-term mechanical stress from frequent opening and closing, while chassis protection parts are constantly exposed to stone impacts, water immersion, and corrosive substances. These conditions place extremely high demands on coating adhesion, impact resistance, and corrosion resistance.

Coatings applied by powder rotary bell spray guns bond tightly with the metal substrate, offering adhesion far superior to traditional coating processes. Even under severe impact, the coating remains firmly attached without peeling. In addition, the coating provides excellent corrosion resistance and anti-aging properties, effectively shielding structural components from environmental damage, slowing metal fatigue, and ensuring long-term structural stability and safety—fully aligning with the automotive industry’s uncompromising safety requirements.

Interior Metal Components

Interior metal components are an essential part of the driving and riding experience. Products such as seat rails and metal air-conditioning vent components must deliver both functional reliability and refined aesthetics.

Seat rails perform critical adjustment functions and are subject to frequent sliding friction, requiring exceptional wear resistance. Metal components of air-conditioning vents remain exposed to the in-cabin environment and must offer good stain resistance, oxidation resistance, and visual consistency with the overall interior design.

Powder rotary bell spray guns precisely control coating thickness, forming uniform and fine coatings on these precision interior metal parts. This enhances wear resistance, ensures smooth and durable seat adjustment, and delivers smooth, even surfaces with consistent color. It also eliminates common defects of traditional spraying methods, such as sagging and particle formation, creating a premium and refined cabin atmosphere.

New Energy Vehicle Battery Components

With the rapid development of the new energy vehicle industry, protection requirements for battery housings and brackets have become increasingly critical, making them an important application area for powder rotary bell spray guns.

As the core power source of NEVs, batteries demand the highest levels of safety and stability. Battery housings and brackets must provide excellent corrosion resistance, insulation performance, and structural strength to ensure reliable operation and vehicle safety.

Powder rotary bell spray guns enable precise coating of battery components. The resulting coating effectively isolates air and moisture to prevent metal corrosion while providing reliable insulation protection to reduce the risk of electrical short circuits. In addition, the high-strength coating enhances the structural stability of battery components, allowing them to withstand vibration and impact during vehicle operation.

Core Advantages & Future Outlook

The widespread adoption of powder rotary bell spray guns in the automotive and automotive components industry is driven by three key advantages:

- High electrostatic transfer efficiency significantly reduces powder waste, lowering production costs while supporting environmental sustainability.

- Excellent coating performance, including corrosion resistance and scratch resistance, fully meets the stringent standards of the automotive industry, ensuring product quality and reliability.

- Seamless compatibility with fully automated automotive production lines, enabling large-scale, standardized manufacturing, significantly improving production efficiency and helping manufacturers gain a competitive edge.

Looking ahead, as the automotive industry continues its transformation toward lightweight design, electrification, and premium positioning, powder rotary bell spray guns will continue to evolve and play a core role in an even broader range of automotive component applications—providing stronger support for technological innovation and quality upgrades across the industry.