From Precision Components to Large-Scale Frames — Enhanced Protection + Automation Empowering the Hardware Industry

Applicable Products:

Hardware accessories (hinges, handles, screws & fasteners), metal tools (wrenches, pliers, garden tools), metal furniture frames (wrought iron tables & chairs, office metal cabinets and frames)

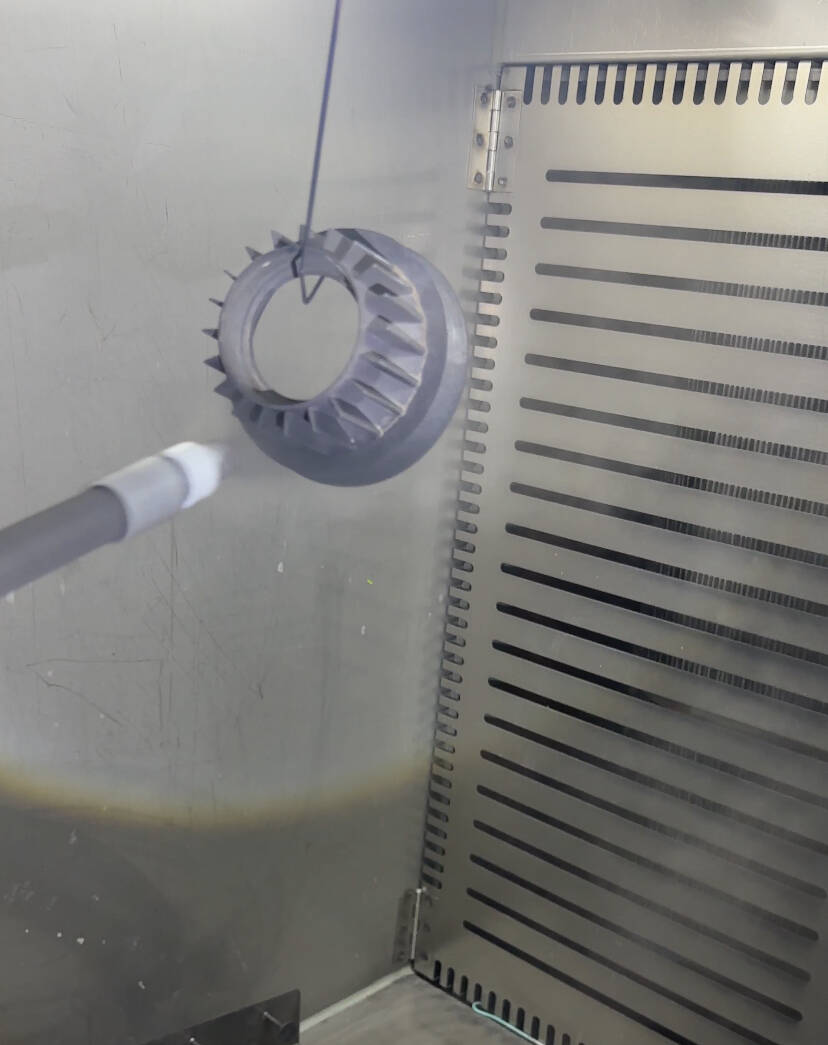

In the field of industrial coating, powder rotary bell spray guns occupy a vital position thanks to their unique technical advantages, and the hardware and metal processing industry is undoubtedly one of their most fundamental and core application areas. From small components in everyday household products to heavy-duty tools used in industrial production, from office metal furniture to outdoor garden equipment, powder rotary bell spray guns are widely applied, providing metal products with a “protective armor” that combines durability and aesthetics.

Hardware Accessories

As essential components in modern industry and daily life, hardware accessories place extremely high demands on surface protection. The smooth operation of hinges, the frequent contact of handles, and the secure fastening of screws all rely on reliable surface coatings. For small and precision components, powder rotary bell spray guns can precisely control the coating dosage, forming a uniform and dense protective layer on the surface. This effectively isolates air, moisture, and impurities, fundamentally preventing metal corrosion while improving wear resistance and extending product lifespan.

Whether it is hinges and handles commonly used in furniture manufacturing or screw fasteners indispensable in mechanical assembly, products coated with powder rotary bell spray guns not only meet long-term durability requirements but also achieve a more refined and consistent appearance.

Metal Tools

Metal tools, the “reliable assistants” in production operations and daily maintenance, are constantly exposed to friction, impact, and humid environments. Surface protection directly affects their performance and service life. Hand tools such as wrenches and pliers frequently come into contact with various materials, while garden tools must withstand prolonged outdoor exposure to wind and rain. These conditions impose strict requirements on coating wear resistance and anti-corrosion performance.

Coatings applied by powder rotary bell spray guns offer strong adhesion and high hardness, firmly bonding to the metal surface. Even under long-term, high-intensity use, they effectively resist wear and corrosion, ensuring stable tool performance. In addition, the uniform coating results in a smooth, even surface, improving handling comfort while enhancing the product’s visual quality.

Metal Furniture Frames

Metal furniture frames are widely used in office environments and outdoor settings due to their strength and durability. The surface treatment of products such as wrought iron tables and chairs or office metal cabinets directly affects both service life and appearance. Outdoor wrought iron furniture is especially prone to rust when exposed to sunlight, rain, and humidity, while office metal cabinets require strong wear and scratch resistance to withstand daily use.

Powder rotary bell spray guns create coatings with uniform thickness and excellent protective performance, effectively shielding the substrate from environmental damage and significantly improving weather resistance and abrasion resistance. More importantly, when integrated with automated coating lines, rotary bell spray guns enable high-efficiency, standardized mass production. This perfectly meets the hardware industry’s large-scale manufacturing requirements while ensuring consistent product quality, boosting productivity, and reducing overall production costs.

Industry Value & Outlook

The application of powder rotary bell spray guns in the hardware and metal processing industry not only solves challenges related to rust prevention and wear resistance but also meets the industry’s growing demand for large-scale and standardized production through seamless compatibility with automated lines. From tiny screw fasteners to large metal furniture frames, their stable and reliable coating performance empowers a wide range of metal products, making them one of the key pieces of equipment driving high-quality development in the hardware industry.

With continuous advancements in industrial technology, the performance of powder rotary bell spray guns will continue to improve, and their applications in the hardware and metal sector will expand further—providing stronger support for product quality enhancement and industry transformation and upgrading.