Q2 Automatic Powder Rotary Cup Spray Gun

Intelligent linkage and strong adaptability, with excellent and efficient atomization performance.

Core Exclusive Features (Suitable for Powder Spraying):

The powder rotating gun head adopts centrifugal + electrostatic composite atomization technology, equipped with spiral/golf ball head quick-release nozzles. It can adapt to various powder and spray width requirements, enabling convenient powder and part replacement while supporting intelligent process control. It achieves high powder deposition rate and precise spraying of dead corners, perfectly matching the rhythm of product changeover in mass production.

Precise Film Thickness + High Paint Deposition Rate + Emission Reduction & Cost Reduction, Meeting Environmental Standards with Zero Rectification

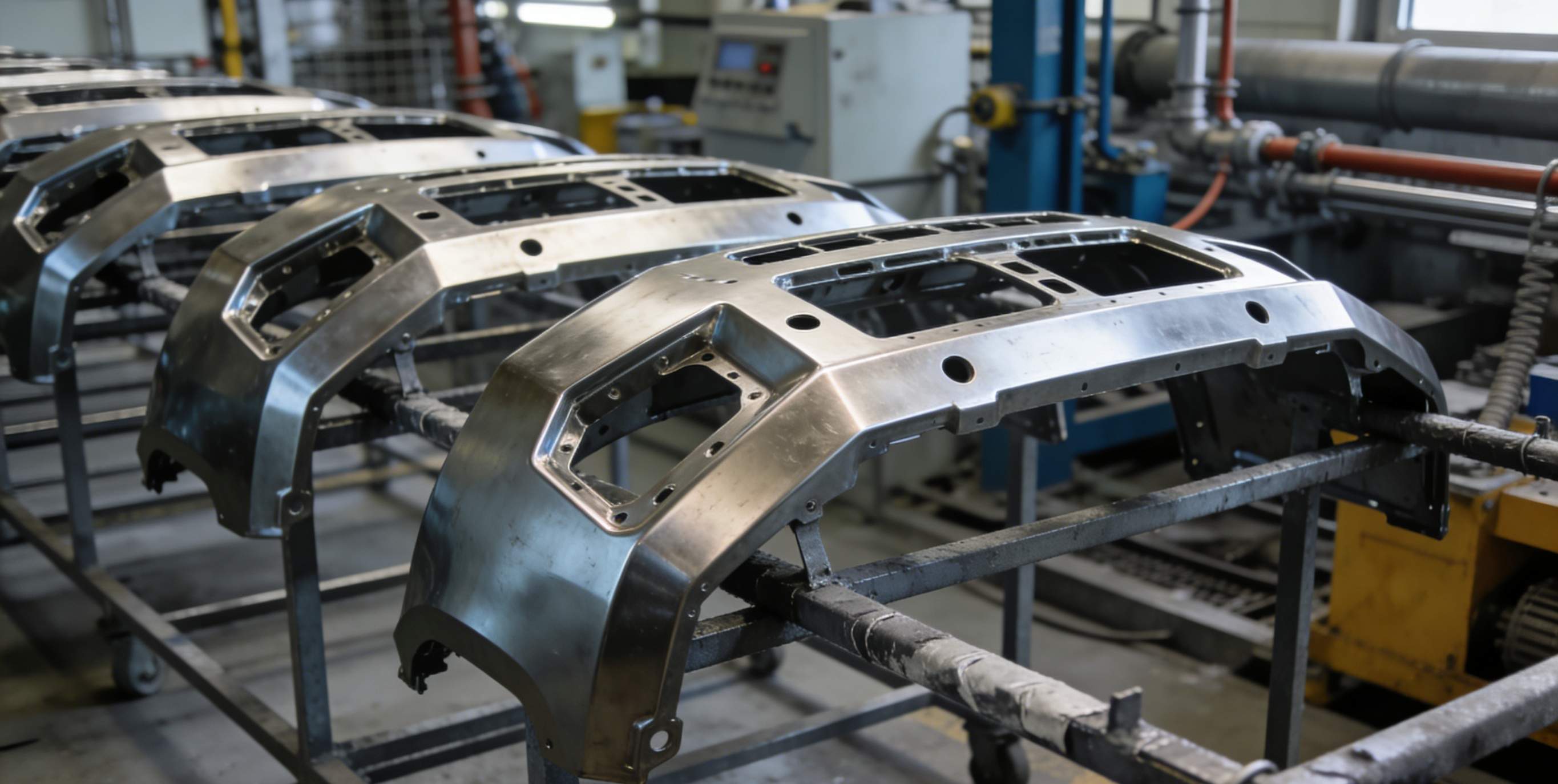

Say goodbye to the industry pain points of traditional car bumper painting: large-area spraying with uneven thickness (thick in the middle, thin on the edges), insufficient paint transfer efficiency (less than 30%), and paint mist polluting the environment and equipment! The automatic rotary cup spray gun, utilizing core high-speed centrifugal atomization technology and a unique wide-angle uniform atomization nozzle design, achieves complete coverage over an ultra-wide spraying area. It thoroughly overcomes the problem of uneven film thickness ("thick in the middle, thin on the edges") encountered with traditional spray guns during large-area painting, precisely controlling the film thickness deviation within ±5μm, ensuring consistent coating thickness and uniform texture across the entire bumper.

Moreover, the high-efficiency adsorption spraying mode of the automatic rotary cup spray gun significantly reduces paint waste, increasing the paint application rate from less than 30% in traditional processes to over 60%, more than doubling paint utilization and helping companies directly reduce paint costs by 40%. In terms of environmental protection, the automatic rotary cup spray gun, through precise mist control and directional spraying, reduces paint mist emissions by 80%, preventing paint mist pollution to the workshop environment and equipment at the source. This eliminates the need for additional investment in upgrading exhaust gas treatment systems, easily meeting stringent environmental standards and achieving environmental compliance without any modifications. Whether it's precise control of spraying quality, effective reduction of production costs, or easy achievement of environmental compliance, the automatic rotary cup spray gun provides an efficient, high-quality, and cost-effective integrated solution for automotive bumper painting, leading the upgrade and transformation of spraying technology.