From detailed texture to mass production capacity, choosing the right spray gun can double the value of lighting fixtures.

The appearance and texture of lighting fixtures directly determine the product's quality level. The spraying process is a crucial step, and the choice of spray gun directly impacts the final quality and market competitiveness. While ordinary spray guns are flexible to operate and have low initial costs, making them popular in the past, they struggle to meet the dual demands of quality and efficiency in the high-end market. In contrast, high-speed rotary cup spray guns, with their four core advantages of "ultra-fine atomization, precise adhesion, high efficiency and energy saving, and automation compatibility," have become the mainstream choice for high-end lighting manufacturing. The following analysis from key dimensions will help you accurately understand the value of rotary cup spray guns.

I. Spraying Effect: A Hardcore Competition of Fineness and Consistency

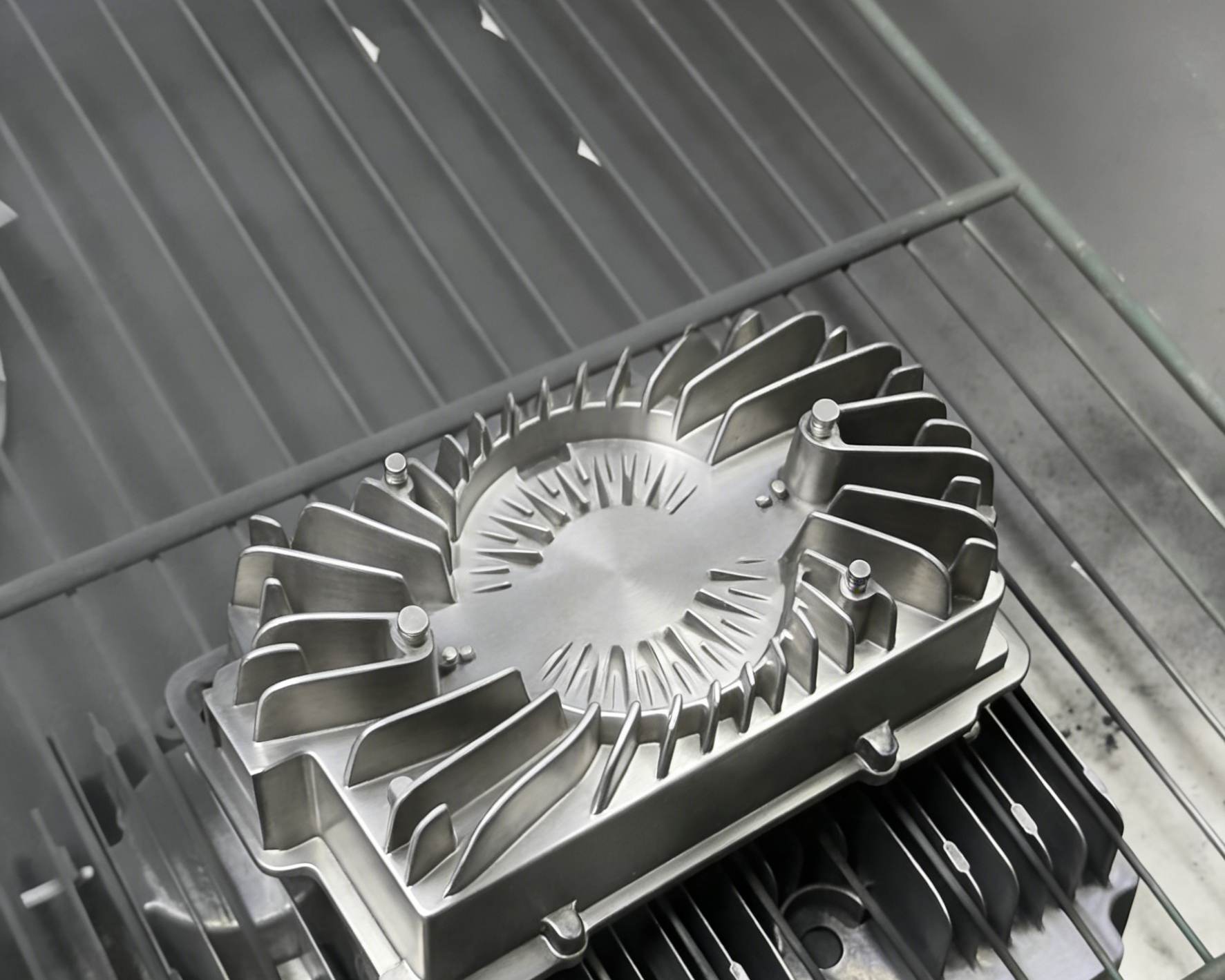

Lighting fixtures often have complex curved surfaces and intricate details, requiring high demands on the uniformity and fineness of the spray coating. Ordinary spray guns use compressed air to atomize the paint, resulting in large and unevenly distributed paint droplets, easily leading to problems such as orange peel, sagging, and incomplete coverage. This is especially true in grooves and corners, where electrostatic shielding effects can cause uneven powder application and inconsistent surface texture.

The core unique selling point of the rotary cup spray gun lies in its dual core technologies of "high-speed centrifugal force + electrostatic adsorption," which allows for a qualitative leap in spraying effect. The high-speed rotating cup (with a rotation speed of up to 30,000-60,000 r/min) breaks the paint into ultra-fine droplets. Combined with the electrostatic field, it creates precise adsorption force, allowing the paint droplets to actively adhere to the workpiece. Even when dealing with complex curved surfaces and intricate grooves of lighting fixtures, it completely avoids the electrostatic shielding problems of ordinary spray guns, achieving comprehensive and uniform coverage without dead spots, thus fundamentally eliminating missed spraying and paint accumulation. The resulting paint film is as smooth as a mirror, and the color and gloss are highly consistent in mass production. This dual advantage of "consistency + fineness" is a core competitive advantage that ordinary spray guns cannot match.

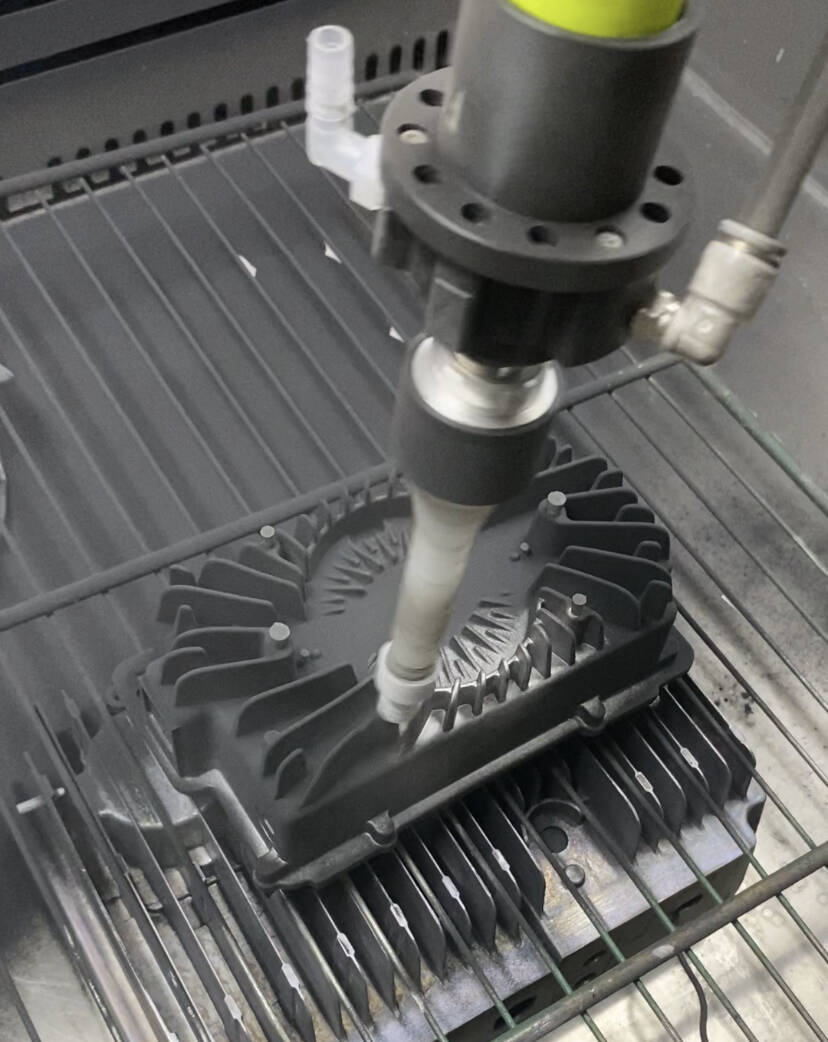

II. Production Efficiency: A Leap from "Manual Craftsmanship" to "Automated Mass Production"

Production capacity is directly related to enterprise costs and delivery capabilities. Ordinary spray guns rely on manual operation, requiring high technical skills. The thin film applied in a single pass requires repeated spraying, resulting in low efficiency. Furthermore, manual operation is unstable and prone to rework due to variations in technique and fatigue, hindering production progress.

Another major unique selling point of the rotary cup spray gun is its "automated adaptability + high-efficiency production capacity," perfectly matching the needs of modern manufacturing for large-scale production. It can seamlessly integrate with robots for 24-hour continuous operation without manual intervention, reducing labor costs and operational risks while avoiding the instability of manual operation. More importantly, it can form a uniform paint film in a single pass, achieving 2-3 times the production capacity of ordinary spray guns per unit of time. The spraying width can be flexibly adjusted, precisely adapting to lighting fixtures of all sizes, from small table lamps to large chandeliers, balancing high production capacity and flexible manufacturing. It is key to improving the core efficiency of the production line.

III. Cost Control: Balancing Short-Term Investment and Long-Term Benefits

Ordinary spray guns have low initial investment and are easy to maintain, suitable for small-batch, multi-style startup scenarios. However, in the long run, their paint utilization rate is only 30%-40%, resulting in significant paint waste and increased costs for spray booth cleaning and environmental treatment. The hidden costs are high.

In terms of cost control, the rotary cup spray gun maximizes long-term benefits with its unique advantage of "high paint utilization rate." Its paint utilization rate reaches 70%-90%, far exceeding the 30%-40% of ordinary spray guns. The savings in paint alone can quickly recoup the initial equipment investment. Coupled with reduced labor costs from automated operation and reduced rework costs due to stable quality, it creates a cost advantage of "slightly higher initial investment, but significantly lower long-term overall costs," making it particularly suitable for medium-to-large-scale production scenarios.

IV. Applicable Scenarios: Precisely Matching Different Production Needs

Ordinary spray guns are suitable for small-batch, multi-category production with frequent style changes, especially for simple flat lighting fixtures or personalized custom products. They offer flexible operation and quick adjustments, but require skilled operators to ensure quality.

The rotary cup spray gun's unique selling point of "high-quality adaptability + full-scenario compatibility" makes it the preferred choice for medium-to-large-scale, high-quality lighting production. Whether it's complex, high-end crystal chandeliers, metal art lamps, or standard smart lighting fixtures, this system can precisely match them. It's also compatible with various non-quick-drying coatings, allowing for easy switching between product categories with simple adjustments. This ensures high-end quality while enhancing production flexibility, making it a key piece of equipment for high-end lighting companies to build their core competitiveness.